|

|

|

|

Permanent Magnet Lifter

|

| Permanent Magnet Lifter |

| Principles: Model PML Permanent Magnet Lifter has strong magnetic path produced by Nd-Fe-B magnetic materials. On and Off of the magnetic path is controlled by turning the manual handle. PML permanent magnetic lifters have magnet as power, and its lifting power will never weaken. |

Application: In loading and unloading, the lifter can hoist iron/steel blocks, cylinders and others onto magnetic materials for linkage or connection. It is very convenient for application in loading, unloading, and moving. PML permanent magnetic lifters are the most ideal lifting facility for factories, docks, warehouses and transportation.

|

1. Features: Lightly and ingeniously structured, easy for application, strong magnetic Attraction power and safe in handling.

2. Use convenient: No fishhook needed, no power needed, and maintenance free.

3. Safe and credibility: Every product that we manufactured had been tested. It ensured to reach or exceed three times safety rate, insures button, which is specially made, will be safe for product.

4. Long life: Our products include pressurize structure, which is special designed, and it could hold the product’s life more than eight years.

|

|

MODEL |

PML-1

100 kg |

PML-4

400 kg |

PML-6

600 kg |

PML-10

1000 kg |

PML-15

1500 kg |

PML-20

2000 kg |

PML-30

3000 kg |

PML-50

5000 kg |

PML-60

6000 kg |

Standard lifting capacity (kg)

|

100

|

400

|

600

|

1000

|

1500

|

2000

|

3000

|

5000

|

6000

|

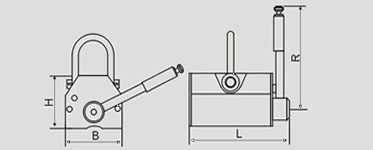

Size

(mm)

|

L

|

115

|

210

|

275

|

325

|

375

|

410

|

485

|

600

|

650

|

B

|

60

|

95

|

115

|

150

|

150

|

175

|

190

|

220

|

240

|

H

|

70

|

100

|

115

|

145

|

145

|

165

|

185

|

220

|

240

|

R

|

145

|

160

|

230

|

280

|

280

|

410

|

510

|

600

|

650

|

Net weight (kg)

|

4

|

10.5

|

18

|

39

|

42

|

75

|

108

|

185

|

225

|

Gross weight(kg)

|

5

|

12.5

|

21

|

43

|

46.5

|

80

|

114

|

192

|

245

|

|

| Other models can be designed and made according to customer’s requirement. |

|

|

Main factors which influence the lifting capacity of permanent Magnetic Lifter.

1 Influenced by thickness and surface quality of the component.

Before operation, it is necessary to find out the percentage of the steel thickness, the lifting capacity is according to the thickness of the component and capacity curve. If its surface roughness Ra is less than 6.8um, the lifter surface gap will not exist, the lifting capacity will be 100%. If the surface roughness Ra is above 6.8um or even worse, the lifter surface gap should be estimated. Find out the percentage that lifting capacity of the lifter may reach from the air gap lifting capacity curve shown in the performance chart. Combine these two factors and calculating the lifting capacity that the lifter may reach. The curves are on the two sides of lifter.

2 Influenced by the composition for steel component.

After measurement, if low-carbon steel component is regarded as a reference and the coefficient of lifting capacity is fixed: the coefficient for medium-carbon steel is 0.95; the coefficient for nigh-carbon steel is 0.90; the coefficient for low-alloy steel is 0.75, and the coefficient for cast iron is 0.50 |

|